-

- NPK Compound Fertilizer Granulation Equipment

Our NPK compound fertilizer granulation equipment is a kind of commonly used fertilizer equipment for producing both organic fertilizers and inorganic fertilizers. Its annual production capacity ranges from 10KT to 500KT. Hence, if you need either organic fertilizer equipment or inorganic fertilizer equipment, please feel free to contact us.

-

- Organic Fertilizer Equipment

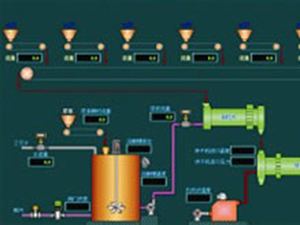

The whole fertilizer production process is centralized controlled. Hence, our compound fertilizer equipment features high automation, flexible and convenient operation. Computer controlled batching and packing systems highly guarantee the accuracy of material batching and fertilizer packing.

-

- Urea Granulation Process Equipment

As a matter of fact, melted-urea has several functions during fertilizer production. It firstly functions as a kind of raw material, and then functions as a liquid to participate in granulating process, and finally produces heat which makes drying process easy.

-

- BB Fertilizer Equipment

The mixing system and material discharging system of our BB fertilizer manufacturing equipment are designed with a unique interior screw mechanism and special three-dimensional structure, which offers a uniform material mixing and smooth material unload.

-

- Sulfur Based Ammoniation Fertilizer Granulation Equipment

Our sulfur based ammoniation fertilizer granulation equipment utilizes a tubular reactor to replace traditional acid-ammonia nozzle, and it now adopts a hanging pipe reactor in stead of original embedded double-nozzle. Thus, improved fertilizer equipment features higher flexibility, higher quality, and higher operational reliability.

-

- 3-300Kt/a SSP/GSSP Fertilizer Plant

During curing process, the mixture should be continuously stirred to increase water evaporation speed and reduce the material temperature, thus ensuring the successful and smooth proceeding of the following production process and improving the material’s physical property. The curing period typically lasts for 3 to 15 days.

-

- Tower Mixed Fertilizer Plant

Our tower mixed fertilizer plant removed the drying system from traditional fertilizer equipment. The drying system usually consumes large quantity of energy. Hence, our fertilizer granulating plant is energy saving.

-

- Potassium Sulfate Fertilizer Equipment

Some key components of our compound fertilizer equipment are made of special materials which are corrosion resistant and durable. Hence, this fertilizer equipment also features long service life.

-

- Rotary Drum Granulator

Our granulation equipment adopts special rubber plate lining or acid resistant stainless steel lining plate. In our rotary drum granulator, the scar can be removed and the burl can be peeled automatically.

-

- Rotary Dryer

Rotary dryer, also known as drum dryer, is widely used for drying materials in cement industry, mineral industry, building material industry, chemical industry, food industry, fertilizer industry, etc.

-

- Rotary Cooler

In rotary cooler, materials to be cooled rotate at a high speed, exchange heat with air through the rotation of shell body and finally are cooled down. The air can be used again and again after cooling.

-

- Spray Granulation Dryer

Our fertilizer granulation dryer is a kind of new type, highly efficient and energy-saving granulating drying equipment which incorporates granulating, drying, internal sieving, internal crushing, internal recycling and some other processes into one.

-

- Rotary Coater / Coating Drum

Our rotary fertilizer coating machine is made up of mainframe, screw conveyor, mixing tank and oil pump. Our fertilizer granule coating equipment adopts powder spraying technology or liquid coating technology to cover the protection layer which can efficiently prevent the compound fertilizers from clotting.

-

- Ball Mill

The centrifugal force generated with the rotation of cylinder elevates the steel balls to a certain height. Then the steel balls fall down to the materials and grind them. After coarsely ground, materials enter into the second chamber through monolayer dividing board. The second chamber is designed with plane lining plate and steel balls.

-

- Jaw Crusher

JC-1 type crushing machine is especially designed for fine crushing in cement industry, mining industry, road construction, quarrying industry, and chemical industry, etc. Its technical index is superior to that of other crushers.

-

- Belt Conveyor

Belt conveyor is composed of mainframe, conveyor belt, two or more pulleys, tension device, and drive device, etc. The pulleys may be powered or unpowered. The powered pulley can cause the belt to move forward so it is called driving pulley, while the unpowered pulley is called idler.

-

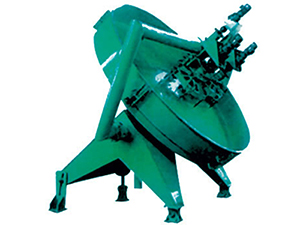

- Disc Granulator

Disc granulator is a kind of fertilizer pelletizing equipment that can be used in fertilizer production. It can process fertilizers into specific shape and the processed particles are of the same size. Our fertilizer granulator machine has the characteristics of simple structure, high granulating efficiency, reliable performance, long service life, easy operation, etc.

-

- Pan Mixer

Vertical mixer is mainly used to mix bulk materials or granular materials, such as feed, fertilizers, putty powders, chemical powders, and so on. It is widely used in metallurgy, fertilizer manufacturing industry, building industry, and some other fields.

-

- Bucket Elevator

Bucket elevator, also known as bucket conveyor, is a kind of continuous conveying machinery mainly used to vertically convey flowable bulk materials, such as grain, fertilizers, coal, cement, clay, sand, ore, and other granular and powdery materials. It can convey a large quantity of bulk materials to a high height steadily.

-

- Fertilizer Bagging Machine

Packing machine is used to pack materials, to beautify them, protect them from damage or make them convenient to transport. The materials to be packed can be liquid materials, bulk materials, lump materials, granular materials, food, and chemicals, just to name a few.

-

- Vibrating Screen

Our vibratory screening equipment has the features of reliable performance, high durability, high screening capacity, easy operation, etc. It can be designed with single deck or double deck. As a professional vibratory screening machine manufacturer in China, we can also design vibration screening machine as per your specifications.

-

- Rotary Drum Screen

Right Machinery Company is a professional rotary screen manufacturer in China. Our rotary drum screen is mainly designed for use in the production of fertilizers. Our rotary screening equipment has the characteristics of easy operation, high performance, long service life, etc.

-

- Pulverizer

Pulverizer machine is mainly used to smash many materials into small granules. The grinding medium can be fertilizer, concrete, coal, rocks, etc. Our pulverizing equipment is mainly used in the production of fertilizers. It can be used individually or in conjunction with other fertilizer equipment.

-

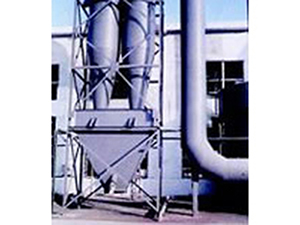

- Cyclone Dust Collector

Characteristics of our industrial dust collector include simple and rational structure, easy operation, good resistance to high temperature, low running cost, high durability, low maintenance cost, high efficiency, etc.

-

- Cement Production Line

The cement production equipment incorporates a crushing machine supporting limestone crushing in outdoor environment. The crushed materials are delivered via a belt conveyor to a round storage yard for pre-homogenization and temporary storage.

-

- Rotary Kiln

Rotary kiln is a kind of pyroprocessing device mainly used to sinter cement clinker. Both dry process and wet process are applicable.

It is widely used in metallurgy industry, chemical industry, cement industry, building industry, etc.

-

- Ball Mill

Ball mill is mainly made up of feeding part, discharging part, rotating part, and drive part. Drive part consists of reduction gear, small drive gear, electrical motor, and electrical control system.

-

- Air-swept Coal Mill

Windswept coal mill is a kind of cement equipment used to dry and grind coal. This coal grinding mill can be used in cement plants, power plants, etc. Our coal grinding mill is mainly made up of feeding device, main bearing, rotation device, discharging device, lubricating system, and electric control system.

-

- Rotary Dryer

Rotary dryer is a kind of cement equipment used to dry materials. This industrial dryer is mainly used in cement industry, mineral industry, building material industry, chemical industry, food industry, fertilizer industry, etc.

-

- Pulse Jet Baghouse Dust Collector

Pulse bag dust collector is a kind of cement equipment widely used for material recovery or smoke management in metallurgy, nonferrous smelting field, construction industry, nonmetal mining industry or other industries that produce massive dust or smoke.

-

- Cyclone Dust Collector

Cyclone dust collector is a kind of cement equipment widely used to purify air in construction industry.

Industrial dust collector is mainly used to collect the large, high concentration non-fibrous dry dust.

-

- Cement Separator

This cement separation equipment is mainly used in cement mill. It can process cement in compliance with new cement standard. The fineness and specific surface area of cement are easy to control.

-

- Bucket Elevator

NE type bucket lifter is a kind of lifting equipment widely used to hoist various bulk materials, such as ores, coal, cement, cement clinker, limestone, and so on.

It can be used in chemical industry, mining industry, metallurgy industry, power industry and some other fields.

-

- Impact Crusher

PF type single-rotor impact crusher is a kind of highly efficient crushing machine widely used to crush ores, rocks and some other materials whose size is not more than 120-350mm. It can be applied in cement industry, chemical industry, and mineral dressing, etc.

-

- Weigh Belt Conveyor

Our steelyard is a kind of industrial steelyard widely used in fertilizer industry, cement industry, metallurgy, building industry, etc.

It adopts intelligent instrument and high precision sensor to collect and control field signal.

-

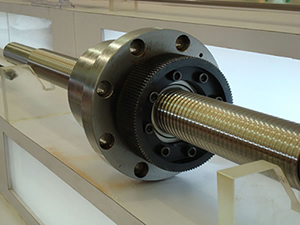

- Ball Screw

Our ball screw assembly has the advantages of high efficiency, low energy consumption, long service life, large loading capacity, high precision, small starting torque, easy maintenance, high sensitivity, easy lubricating, etc.

-

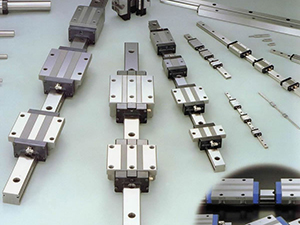

- Linear Guide

Our straight line guide has the features of high precision, long service life, high efficiency, low frictional resistance, high speed and low noise. Finite element analysis is utilized to optimize the design of raceway cross-section, to acquire a larger rated load and rigidity.

Established in 1954, Right Machinery Company is an experienced fertilizer equipment manufacturer in China. We are engaged in the production and sale of NPK compound fertilizer granulation equipment, organic fertilizer equipment, cement equipment, and so on. We have obtained ISO9001:2000 certification and ISO9001:2008 certification.

Our rationally designed fertilizer equipment enjoys high degree of automation. During the batching process, the moisture, temperature, wind pressure and other technical indexes are all automatically controlled. Your special requirements on designing fertilizer equipment can also be satisfied.

Our cement equipment has the characteristics of simple structure, durability, easy maintenance, high reliability, and low running cost.

Our rolling functional units are characterized by low power consumption and high precision. They are available in various specifications, to meet your different requirements.

Due to their high quality and low price, our rotary kilns, ball mills, windswept coal mills, ball screw/ guiders and press brakes are well received in Singapore, Malaysia, Indonesia, India, Pakistan, Iran, Turkey, Egypt, Nigeria, Saudi Arabia and more.

We are near to highways, airports and sea ports. This will facilitate the transport of your goods.

Welcome to visit our company. Please contact us if you have any problem.