Fertilizer Production Line

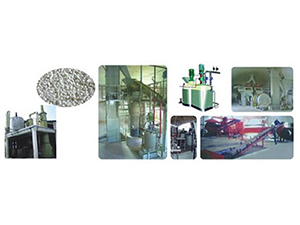

Fertilizer equipment is mainly used in the production of organic fertilizers and inorganic fertilizers. As a professional fertilizer production equipment manufacturer in China, we can produce NPK compound fertilizer granulation equipment, urea granulation process equipment, BB fertilizer equipment, tower mixed fertilizer plants, potassium sulfate fertilizer equipment, rotary drum granulators, rotary dryers, ball mills, vertical mixers, vibrating screens, and so on.

-

- NPK Compound Fertilizer Granulation Equipment

Our NPK compound fertilizer granulation equipment is a kind of commonly used fertilizer equipment for producing both organic fertilizers and inorganic fertilizers. Its annual production capacity ranges from 10KT to 500KT. Hence, if you need either organic fertilizer equipment or inorganic fertilizer equipment, please feel free to contact us.

-

- Organic Fertilizer Equipment

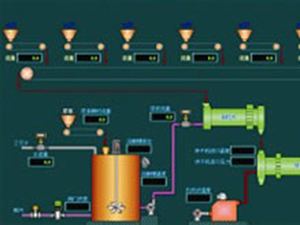

The whole fertilizer production process is centralized controlled. Hence, our compound fertilizer equipment features high automation, flexible and convenient operation. Computer controlled batching and packing systems highly guarantee the accuracy of material batching and fertilizer packing.

-

- Urea Granulation Process Equipment

As a matter of fact, melted-urea has several functions during fertilizer production. It firstly functions as a kind of raw material, and then functions as a liquid to participate in granulating process, and finally produces heat which makes drying process easy.

-

- BB Fertilizer Equipment

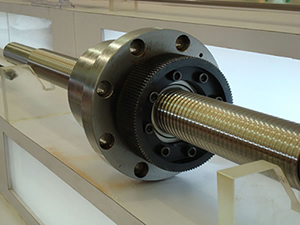

The mixing system and material discharging system of our BB fertilizer manufacturing equipment are designed with a unique interior screw mechanism and special three-dimensional structure, which offers a uniform material mixing and smooth material unload.

-

- Sulfur Based Ammoniation Fertilizer Granulation Equipment

Our sulfur based ammoniation fertilizer granulation equipment utilizes a tubular reactor to replace traditional acid-ammonia nozzle, and it now adopts a hanging pipe reactor in stead of original embedded double-nozzle. Thus, improved fertilizer equipment features higher flexibility, higher quality, and higher operational reliability.

-

- 3-300Kt/a SSP/GSSP Fertilizer Plant

During curing process, the mixture should be continuously stirred to increase water evaporation speed and reduce the material temperature, thus ensuring the successful and smooth proceeding of the following production process and improving the material’s physical property. The curing period typically lasts for 3 to 15 days.

-

- Tower Mixed Fertilizer Plant

Our tower mixed fertilizer plant removed the drying system from traditional fertilizer equipment. The drying system usually consumes large quantity of energy. Hence, our fertilizer granulating plant is energy saving.

-

- Potassium Sulfate Fertilizer Equipment

Some key components of our compound fertilizer equipment are made of special materials which are corrosion resistant and durable. Hence, this fertilizer equipment also features long service life.

Characteristics of Fertilizer Production Line

- Our fertilizer equipment is designed with compact and rational structure.

- It has the features of low energy consumption, reliable performance, easy maintenance, steady running, high efficiency, etc.

- Our fertilizer manufacturing plant can be used in the production of bio-fertilizers, magnetized fertilizers, ammonium fertilizers, medicines, chemicals, feed and some other granular materials.

- It will not produce waste water, waste gas or waste residue.

In addition to compound fertilizer equipment, we also offer rotary kilns, bucket lifters, impact crushers, separators, shearing machines, and press brake, etc. These products can be used in mining industry, fertilizer industry, building industry, chemical industry, and some other fields. They are well received in Vietnam, Malaysia, India, Iran, Turkey, Egypt, Thailand, Nigeria, Saudi Arabia and more.

Please contact us if you are interested in our organic fertilizer equipment, inorganic fertilizer equipment, main fertilizer equipment or other products.