Plate Rolling Machine

This product has been discontinued and removed from our shelves.

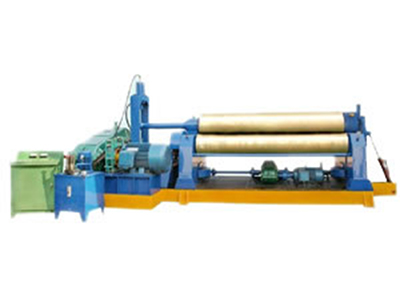

Characteristics of W11 Mechanical 3-roller Symmetrical Plate Rolling Machine

- W11 mechanical 3-roller symmetrical plate rolling machine is designed with three roller symmetrical structure.

- With the transmission of lead screw, nut and worm, the upper roller moves vertically in the center between the two lower rollers.

- The two lower rollers rotate and can provide torque for plate materials through the engagement of the output gear of speed reducer and the gear of the lower rollers.

- This plate rolling machine has a compact structure and is easy to operate and maintain.

| Specification | Max. Thickness of Coiled Plate | Max. Width of Coiled Plate | Yielding Limit of Sheet Metal | Coiling Speed | Min. Full Loading Diameter of Coiled Plate | Diameter of Top Shaft | Diameter of Bottom Shaft | Central Distance Between Bottom Shafts | Main Motor Power |

| mm | mm | mm | m/min | mm | mm | mm | mm | kw | |

| W11-4×1500 | 4 | 1500 | 245 | 5 | 300 | 150 | 140 | 185 | 3 |

| W11-6×1500 | 6 | 1500 | 245 | 5 | 380 | 160 | 140 | 220 | 4 |

| W11-6×2000 | 6 | 2000 | 245 | 4.5 | 380 | 170 | 160 | 260 | 5.5 |

| W11-6×3200 | 6 | 3200 | 245 | 4.5 | 380 | 220 | 180 | 280 | 7.5 |

| W11-8×2000 | 8 | 2000 | 245 | 4.5 | 400 | 185 | 170 | 260 | 5.5 |

| W11-8×2500 | 8 | 2500 | 245 | 4.5 | 550 | 240 | 180 | 280 | 7.5 |

| W11-12×2000 | 12 | 2000 | 245 | 4.5 | 550 | 240 | 180 | 280 | 7.5 |

| W11-12×2500 | 12 | 2500 | 245 | 4.5 | 600 | 260 | 220 | 320 | 11 |

| W11-12×3000 | 12 | 3000 | 245 | 4 | 700 | 280 | 240 | 360 | 11 |

| W11-16×2000 | 16 | 2000 | 245 | 4 | 600 | 260 | 220 | 320 | 7.5 |

| W11-16×2500 | 16 | 2500 | 245 | 4 | 700 | 280 | 240 | 360 | 11 |

| W11-16×3000 | 16 | 3000 | 245 | 4 | 850 | 340 | 260 | 430 | 15 |

| W11-20×2000 | 20 | 2000 | 245 | 4 | 700 | 280 | 240 | 360 | 11 |

| W11-20×2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 260 | 430 | 15 |

| W11-25×2000 | 25 | 2000 | 245 | 4 | 850 | 330 | 270 | 430 | 15 |

| W11-25×2500 | 25 | 2500 | 245 | 4 | 900 | 370 | 270 | 480 | 22 |

| W11-30×2500 | 30 | 2500 | 245 | 4 | 1200 | 420 | 360 | 550 | 30 |

| W11-30×3000 | 30 | 3000 | 245 | 4 | 1200 | 450 | 390 | 600 | 37 |

Characteristics of W11 Hydraulic 3-roller Symmetrical Plate Rolling Machine

- W11 hydraulic 3-roller symmetrical plate rolling machine is designed with three roller symmetrical structure.

- The hydraulic oil in hydraulic cylinder pushes the plunger to drive the upper roller moving vertically in the center between the two lower rollers.

- The two lower rollers rotate and can provide torque for plate materials through the engagement of the output gear of speed reducer and the gear of the lower rollers.

- This plate rolling machine has a compact structure and is easy to operate and maintain.

| Specification | Max. Thickness of Coiled Plate | Max. Width of Coiled Plate | Yielding Limit of Sheet Metal | Coiling Speed | Min. Full Loading Diameter of Coiled Plate | Diameter of Top Shaft | Diameter of Bottom Shaft | Central Distance Between Bottom Shafts | Main Motor Power | Hydraulic Motor Power |

| mm | mm | mm | m/min | mm | mm | mm | mm | kw | kw | |

| W11Y-30×2000 | 30 | 2000 | 245 | 4 | 1200 | 360 | 290 | 480 | 22 | 7.5 |

| W11Y-25×2500 | 25 | 2500 | 245 | 4 | 1200 | 370 | 300 | 480 | 22 | 7.5 |

| W11Y-30×2500 | 30 | 2500 | 245 | 4 | 1200 | 420 | 360 | 550 | 30 | 11 |

| W11Y-25×3000 | 25 | 3000 | 245 | 4 | 1200 | 430 | 370 | 550 | 30 | 11 |

| W11Y-30×3000 | 30 | 3000 | 245 | 4 | 1200 | 450 | 390 | 600 | 30 | 11 |

| W11Y-40×2500 | 40 | 2500 | 245 | 3.5 | 1400 | 500 | 400 | 600 | 37 | 15 |

| W11Y-40×3000 | 40 | 3000 | 245 | 3.5 | 1600 | 540 | 440 | 600 | 45 | 18.5 |

| W11Y-50×3000 | 50 | 3000 | 245 | 3.5 | 2000 | 580 | 480 | 750 | 55 | 22 |

| W11Y-60×3000 | 60 | 3000 | 245 | 3.5 | 2400 | 660 | 560 | 800 | 75 | 30 |

| W11Y-70×3000 | 70 | 3000 | 245 | 3.5 | 2800 | 710 | 620 | 850 | 90 | 37 |

| W11Y-80×3000 | 80 | 3000 | 245 | 3.5 | 3200 | 770 | 680 | 900 | 90 | 37 |

| W11Y-90×3000 | 90 | 3000 | 245 | 3.5 | 3600 | 820 | 730 | 950 | 110 | 45 |

| W11Y-100×3000 | 100 | 3000 | 245 | 3.5 | 4000 | 860 | 770 | 1000 | 110 | 45 |

| W11Y-110×3000 | 110 | 3000 | 245 | 3.5 | 4000 | 900 | 810 | 1080 | 132 | 55 |

| W11Y-120×3000 | 120 | 3000 | 245 | 3.5 | 4800 | 950 | 860 | 1160 | 132 | 55 |

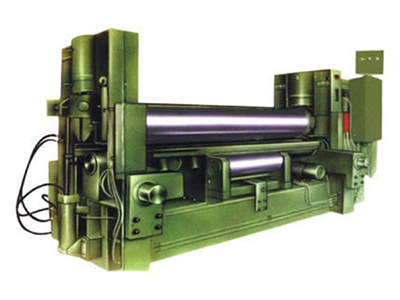

Characteristics of W11S series Upper Roller Universal Plate Rolling Machine

- After you have set the length of straight flange freely, the upper roller can directly force on the ends of the materials to pre-bend them. This plate rolling machine provides high pre-bending accuracy.

- Our upper roller universal plate rolling machine adopts NC control to ensure the high efficiency and easy operation.

- The finished plate materials are of high precision. The upper roller which seems like a drum, together with lower rollers which has carrier rollers below, can process the sheet and thick boards into your desired products through continuously bending.

- Since the two lower rollers are fixed and only the upper roller moves up and down, left and right, the plate materials will not move with the working rollers. So the safety of operators can be guaranteed.

- Our plate rolling machine is designed as a whole, so it is quite convenient and easy to move the machine. No anchor bolt is needed.

- According to different usages of plate materials, our plate rolling machine can carry out different control modes. TNC (upper NC) is applied in the condition that the required products are of many varieties and small quantity. T&BNC (upper, lower NC) is utilized in the condition that the required products are of few varieties and large quantity.

- The plate materials can be process into O type, U type and multistage R type by our plate rolling machine. If the plate rolling machine is fitted with conical drum device, it can also be used to process materials into conical drum.

| Model | Max. rolling thickness (mm) | Max. pre-rolling thickness (mm) | Max. Plate width (mm) | Diameter of upper roller(mm) | Diameter of lower roller(mm) | Main motor power (kw) | ||

| for Driving | for Hydraulic | for Shift | ||||||

| W11SNC-12×2000 | 12 | 10 | 2000 | 250 | 145 | 4.5 | 4 | 1.1 |

| W11SNC-14×2000 | 10 | 12 | 2000 | 250 | 145 | 5.5 | 4 | 1.1 |

| W11SNC-15×2000 | 14 | 12 | 2000 | 250 | 150 | 5.5 | 4 | 1.1 |

| W11SNC-16×2000 | 16 | 14 | 2000 | 255 | 150 | 7.5 | 4 | 1.1 |

| W11SNC-16×2500 | 16 | 16 | 2500 | 300 | 165 | 15 | 4 | 1.1 |

| W11SNC-17×2500 | 16 | 16 | 2500 | 300 | 180 | 15 | 5.5 | 1.5 |

| W11SNC-18×3000 | 18 | 16 | 3000 | 350 | 180 | 15 | 5.5 | 1.5 |

| W11SNC-20×2500 | 20 | 21 | 2500 | 330 | 180 | 15 | 5.5 | 1.5 |

| W11SNC-20×3000 | 20 | 21 | 3000 | 375 | 200 | 18.5 | 5.5 | 2.2 |

| W11SNC-25×2500 | 25 | 21 | 2500 | 380 | 220 | 22 | 5.5 | 2.2 |

| W11SNC-25×3000 | 25 | 21 | 3000 | 425 | 235 | 30 | 7.5 | 2.2 |

| W11SNC-25×3500 | 25 | 25 | 3500 | 440 | 235 | 30 | 7.5 | 2.2 |

| W11SNC-25×6000 | 25 | 25 | 6000 | 630 | 300 | 45 | 7.5 | 2.2 |

| W11SNC-30×2500 | 30 | 28 | 2500 | 410 | 235 | 30 | 7.5 | 4 |

| W11SNC-30×3000 | 30 | 30 | 3000 | 450 | 250 | 37 | 7.5 | 4 |

| W11SNC-32×3000 | 32 | 30 | 3000 | 480 | 260 | 37 | 7.5 | 4 |

| W11SNC-35×2500 | 35 | 32 | 2500 | 460 | 260 | 37 | 11 | 4 |

| W11SNC-35×3000 | 35 | 32 | 3000 | 510 | 275 | 45 | 11 | 4 |

| W11SNC-40×2500 | 40 | 32 | 2500 | 500 | 275 | 45 | 11 | 4 |

| Model | Max. rolling thickness (mm) | Max. pre-rolling thickness(mm) | Max. Plate width(mm) | Diameter of upper roller(mm) | Diameter of lower roller(mm) | Main motor power (kw) | ||

| For Driving | For Hydraulic | For Shift | ||||||

| W11SNC-40×3000 | 40 | 50 | 4000 | 750 | 420 | 90 | 15 | 5.5 |

| W11SNC-40×4000 | 40 | 55 | 5000 | 820 | 440 | 90 | 15 | 5.5 |

| W11SNC-45×3000 | 45 | 55 | 3000 | 650 | 380 | 75 | 22 | 5.5 |

| W11SNC-45×4000 | 45 | 60 | 4000 | 780 | 440 | 90 | 22 | 5.5 |

| W11SNC-50×3000 | 50 | 60 | 4000 | 810 | 460 | 90 | 22 | 5.5 |

| W11SNC-50×4000 | 50 | 65 | 3000 | 710 | 420 | 75 | 22 | 5.5 |

| W11SNC-55×4000 | 55 | 70 | 4000 | 840 | 480 | 110 | 22 | 7.5 |

| W11SNC-55×5000 | 55 | 70 | 3000 | 740 | 440 | 90 | 22 | 7.5 |

| W11SNC-60×3000 | 60 | 75 | 3000 | 770 | 460 | 90 | 22 | 7.5 |

| W11SNC-60×4000 | 60 | 85 | 4000 | 900 | 520 | 110 | 22 | 7.5 |

| W11SNC-65×4000 | 65 | 85 | 3000 | 800 | 480 | 110 | 22 | 7.5 |

| W11SNC-70×3000 | 70 | 95 | 3000 | 860 | 480 | 110 | 22 | 7.5 |

| W11SNC-70×4000 | 70 | 100 | 4000 | 940 | 560 | 132 | 22 | 7.5 |

| W11SNC-75×3000 | 75 | 110 | 4000 | 990 | 600 | 160 | 22 | 7.5 |

| W11SNC-80×3000 | 80 | 120 | 3000 | 900 | 580 | 160 | 22 | 7.5 |

| W11SNC-80×4000 | 80 | 130 | 3000 | 960 | 600 | 160 | 22 | 7.5 |

| W11SNC-85×3000 | 85 | 140 | 3000 | 1080 | 650 | 2x90 | 22 | 7.5 |

| Model | Max. rolling thickness(mm) | Max .pre-rolling thickness(mm) | Max. Plate width(mm) | Diameter of upper roller(mm) | Diameter of lower roller(mm) | Main motor power (kw) | ||

| For Driving | For Hydraulic | For Shift | ||||||

| W11SNC-100×4000 | 100 | 100 | 4000 | 940 | 560 | 132 | 22 | 5.5 |

| W11SNC-110×4000 | 110 | 110 | 4000 | 990 | 600 | 160 | 22 | 5.5 |

| W11SNC-120×3000 | 120 | 120 | 3000 | 900 | 580 | 160 | 22 | 5.5 |

| W11SNC-130×3000 | 130 | 130 | 3000 | 960 | 600 | 160 | 22 | 7.5 |

| W11SNC-150×3000 | 150 | 150 | 3000 | 1080 | 650 | 2x90 | 22 | 7.5 |

| W11SNC-160×4000 | 160 | 160 | 4000 | 1260 | 670 | 2x90 | 22 | 7.5 |

Thank you for visiting our website.

Established in 1954, Right Machinery Company is a professional plate rolling machine manufacturer in China. We mainly produce fertilizer equipment, cement equipment, plate rolling machines, press brakes, and shearing machines, etc.

They are all of high quality and low price. They are well received in Singapore, Malaysia, Indonesia, India, Pakistan, Iran, Turkey, Nigeria, Saudi Arabia and more.

Located in Nantong City in Jiangsu Province, we are near to highways and sea ports. This can facilitate the transport of your goods.

Please contact us if you are interested in our plate rolling machines, potassium sulfate fertilizer equipment, bucket lifters, or other products.

-

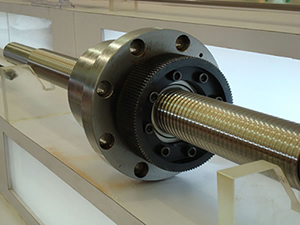

- Ball Screw

Our ball screw assembly has the advantages of high efficiency, low energy consumption, long service life, large loading capacity, high precision, small starting torque, easy maintenance, high sensitivity, easy lubricating, etc ...